Software Structure

Features

Download

Application

Introduction:

The grounding monitoring system is mainly used to monitor the real-time static electricity protection status of the wrist strap and the equipment grounding. If there is an abnormality, it can report the fault location, number and category to the relevant operation or monitoring and management personnel in time and accurately to prevent static electricity hazards and operational safety in advance.

One host can monitor 4 wrist straps and 4 devices (including table pads) online at the same time.If multiple machines are online, real-time network monitoring can connect up to 50 hosts to work together.At the same time, the multifunctional ground monitoring system transmits each online wrist strap/ankle strap and device ground monitoring data information to the PC through the monitoring network in real time and records it for archiving. The management or inspection personnel can call and view at any time.The grounding monitoring system is a new product developed by our company in the field of anti-static. It can effectively monitor the grounding of production auxiliary tools and equipment. It allows real-time monitoring, alarming, recording, and querying of grounding. Its functions are comprehensive and powerful.

Technical parameters of grounding system:

The design standard conforms to the national standard QJ 2846-1996 "General Specification for Anti-static Operating System"

Indicator green: qualified

Red indicator light and sound alarm: unqualified

Yellow indicator light indicates: poor contact, low resistance

Gray indicator light indicates: the station is closed or not working

Working principle of intelligent grounding network monitoring:

The grounding monitoring system is mainly used to monitor the real-time static electricity protection status of the wrist strap and the equipment grounding. If there is an abnormality, it can report the fault location, number and category to the relevant operation or monitoring and management personnel in time and accurately to prevent static electricity hazards and operational safety in advance.

One host can monitor 4 wrist straps and 4 devices (including table pads) online at the same time.If multiple machines are online, real-time network monitoring can connect up to 50 hosts to work together.At the same time, the multifunctional ground monitoring system transmits each online wrist strap/ankle strap and device ground monitoring data information to the PC through the monitoring network in real time and records it for archiving. The management or inspection personnel can call and view at any time.The grounding monitoring system is a new product developed by our company in the field of anti-static. It can effectively monitor the grounding of production auxiliary tools and equipment. It allows real-time monitoring, alarming, recording, and querying of grounding. Its functions are comprehensive and powerful.

Technical parameters of grounding system:

The design standard conforms to the national standard QJ 2846-1996 "General Specification for Anti-static Operating System"

| Wristband monitoring resistance | Wrist strap ground monitoring resistance value range 750K-30MΩ |

| Equipment monitoring resistance | The range of equipment/mat ground monitoring resistance is 0-100Ω, and the factory setting upper limit is 4Ω |

| Monitoring accuracy (%) | The grounding monitoring resistance value of the wrist strap has an accuracy of 15%, and the grounding monitoring voltage accuracy of the equipment/bench pad is 10%. |

| Communication mode | The computer monitoring communication device is USB to RS485 / 422 serial port communicator |

| Operating environment | Anti-static workshop, -10~50°C |

| Display lamp | OK-green; H-red; l-yellow |

| Alarm rate | Host alarm response time ≤1S, PC monitoring alarm response time <3S |

| Shell | A3 steel powder spraying |

| Power Supply | Input: 220 VAC / 50 Hz, output: 9 VDC / 0.45 a * 2 |

| Maximum power | 6W |

| Dimensions | 273 (L ) x137(W)x52(H)MM |

| Host weight | 1.43KG |

Red indicator light and sound alarm: unqualified

Yellow indicator light indicates: poor contact, low resistance

Gray indicator light indicates: the station is closed or not working

Working principle of intelligent grounding network monitoring:

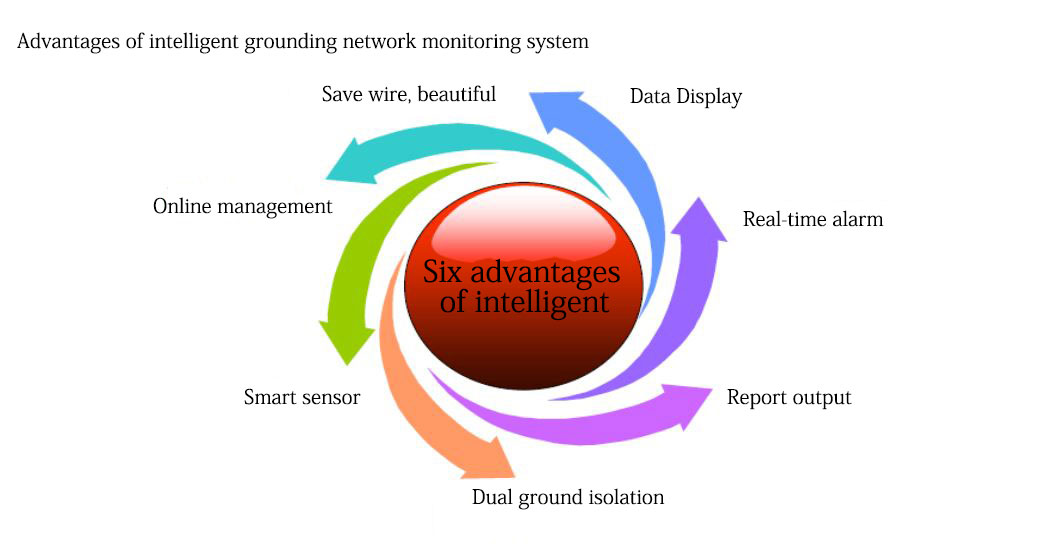

Features of grounding networking system:

A host has 4 wrist straps and 4 device interfaces (including pads).

When using the networked online monitoring function, multiple machines are used in series, and the maximum number is 50.

Adopt resistive monitoring principle, double loop grounding to ensure reliable grounding of monitored objects.

The internal circuit of the host adopts photoelectric isolation technology to effectively separate the electrostatic ground from the equipment ground, which is more safe and reliable.

The alarm threshold can be adjusted according to the actual grounding warning standards in different occasions and regions.

The operator can remotely access the monitoring through the network, and dynamically monitor the wearing of the human wrist strap, the pad and the grounding of the equipment in real time.

Adopt buzzer alarm sound and LED indicator alarm and PC upper computer system alarm and record it.

Convenient installation, low maintenance and management costs, simple replacement and maintenance of accessories, and ready to use.

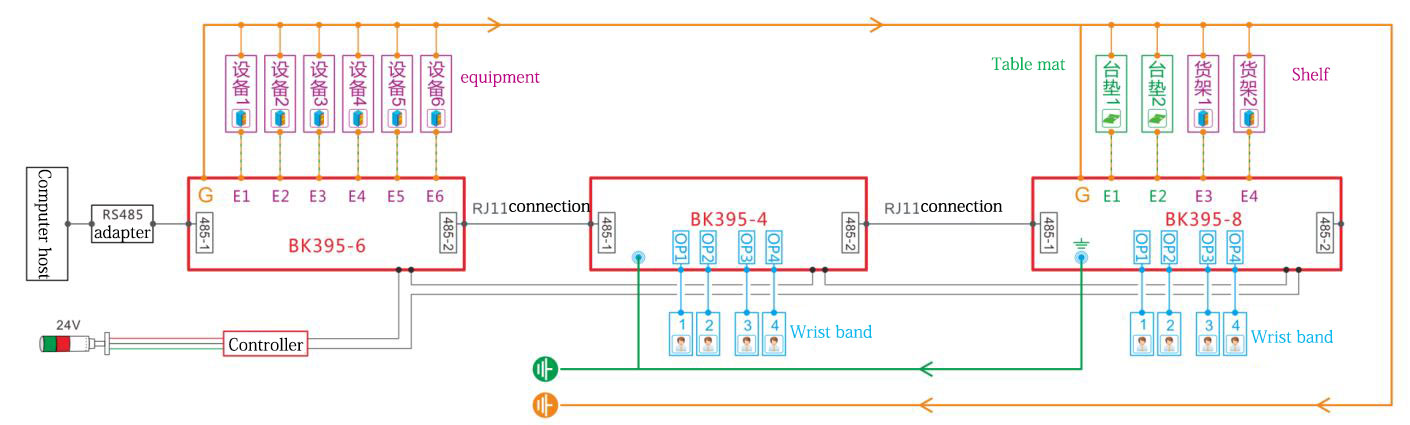

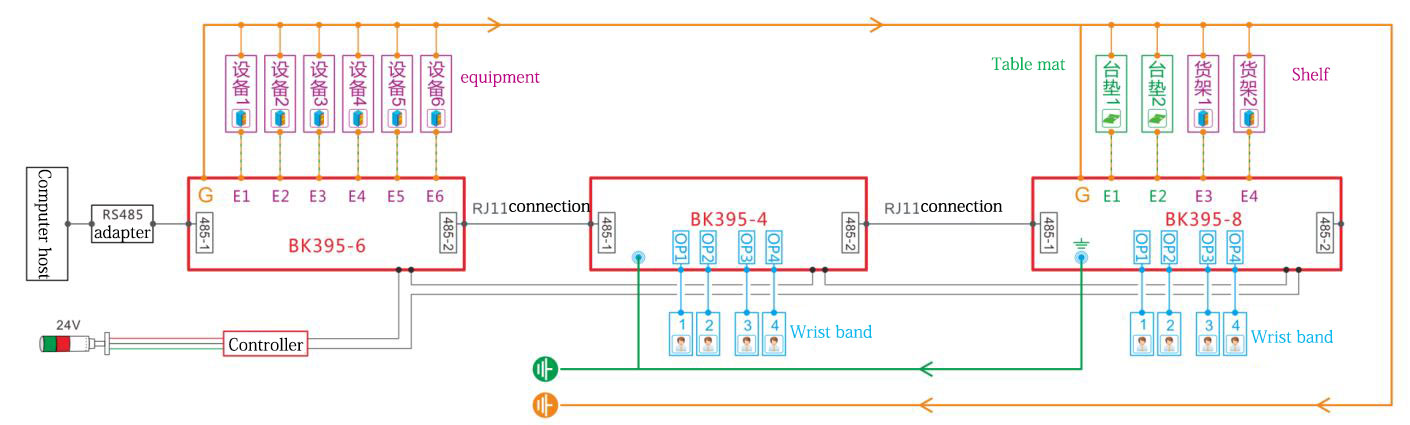

Grounding system networking and function introduction:

Using diffuse reflection infrared automatic sensing device, when the human body is detected, the human body wrist strap is grounded intelligently.

The sensing device can be flexibly adjusted according to the position of the human body to reduce blind areas. The human body induction signal detection lasts for 2-3 seconds, which can effectively stop the flow of people and trigger the induction to cause false alarms.

Table mat/equipment grounding abnormal, host alarm + alarm light alarm + computer sound alarm.

The wrist strap is grounded abnormally, the wrist strap inserts the label alarm + host alarm + alarm light alarm + computer sound alarm.

Through the scene, alarm lights, and host computer software, according to the corresponding machine number and port (location information) of the alarm, the fault is eliminated and the alarm is eliminated. The state change at this time is recorded in the database and can be viewed or exported.

Intelligent on-site alarms, computer management and database storage can efficiently and reliably realize integrated intelligent management of factory ESD.

A host has 4 wrist straps and 4 device interfaces (including pads).

When using the networked online monitoring function, multiple machines are used in series, and the maximum number is 50.

Adopt resistive monitoring principle, double loop grounding to ensure reliable grounding of monitored objects.

The internal circuit of the host adopts photoelectric isolation technology to effectively separate the electrostatic ground from the equipment ground, which is more safe and reliable.

The alarm threshold can be adjusted according to the actual grounding warning standards in different occasions and regions.

The operator can remotely access the monitoring through the network, and dynamically monitor the wearing of the human wrist strap, the pad and the grounding of the equipment in real time.

Adopt buzzer alarm sound and LED indicator alarm and PC upper computer system alarm and record it.

Convenient installation, low maintenance and management costs, simple replacement and maintenance of accessories, and ready to use.

Grounding system networking and function introduction:

Using diffuse reflection infrared automatic sensing device, when the human body is detected, the human body wrist strap is grounded intelligently.

The sensing device can be flexibly adjusted according to the position of the human body to reduce blind areas. The human body induction signal detection lasts for 2-3 seconds, which can effectively stop the flow of people and trigger the induction to cause false alarms.

Table mat/equipment grounding abnormal, host alarm + alarm light alarm + computer sound alarm.

The wrist strap is grounded abnormally, the wrist strap inserts the label alarm + host alarm + alarm light alarm + computer sound alarm.

Through the scene, alarm lights, and host computer software, according to the corresponding machine number and port (location information) of the alarm, the fault is eliminated and the alarm is eliminated. The state change at this time is recorded in the database and can be viewed or exported.

Intelligent on-site alarms, computer management and database storage can efficiently and reliably realize integrated intelligent management of factory ESD.

下一篇:沒(méi)有了